Manufacturing

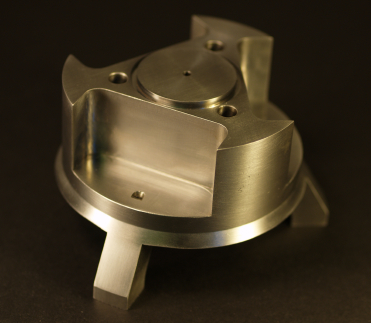

At Davis Tool, we can provide more than just precision machined parts. We can assist you with the entire manufacturing process, from start to finish. Our innovative manufacturing services range from OEM component manufacturing to complete turnkey production, as well as a number of value-added services to help you keep manufacturing costs low.

- Manufacturing facilities operate 24 hours a day, so your project is always moving forward.

- We utilize a standard set of tools to reduce and eliminate setup times.

- Repeat jobs run very efficiently on our cell workcenters. The operator loads the raw material and the machine begins manufacturing your parts.

At Davis Tool, we embrace technological advances in manufacturing techniques in order to be a leader in the industry. We use laser for cutting sheet metals at high speed and large capacity CNC machines for your parts ranging in toughness from aluminum to titanium.

|

|

|

|

MRP (Manufacturing Requirements Planning)

Davis Tool utilizes a sophisticated MRP system developed and maintained in-house to plan and schedule the requirements of your projects. This system gives Davis Tool the ability to deliver your complex projects faster with higher quality, accuracy and efficiency.

Our system provides:

- Better control of inventories allows Davis Tool to keep costs and lead times low.

- Intelligent scheduling through all phases of manufacturing shortens time to delivery

- Productive relationships with suppliers helps keep our costs low and competitive.

- Actively developed and maintained on-site keeping it current with shifting technologies, markets and opportunities.